This helps in delivering the product at low cost and faster timelines.

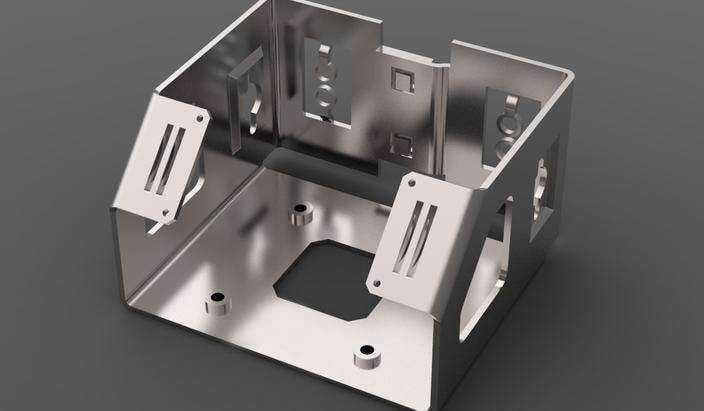

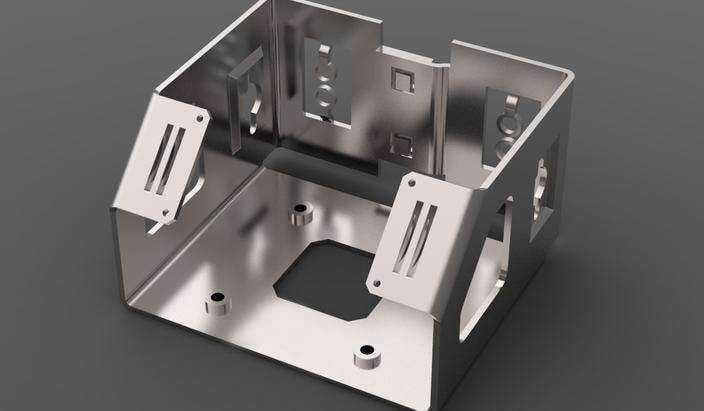

Sheet metal bracket design guidelines.

This is an example of dfm guidelines for sheetmetal fabrication.

A 1 degree tolerance on all bend angles.

Depending on the alloy.

The guidelines were designed to aid mainly novice design engineers in early stages of component development.

However for typical parts meant to be cost effective and easily produced the following tips should be useful.

In a sheet metal design specifying hole sizes locations and their alignment is critical.

Beyond sheet metal properties and available materials here are eight ways to improve sheet metal parts.

Sheet metal design guidelines are followed to design quality sheet metal enclosures.

Following all sheet metal design guidelines is very difficult in the complex part.

Form height to thickness ratio to determine the minimum form height for sheet metal use the following formula.

So you decided to design your own sheet metal part.

It is always better to specify hole diameters that are greater than the sheet s thickness t.

In low carbon steel sheet metal the minimum radius of a bend should be one half the material thickness or 0 80 mm.

Aside from that a variety of metals is available including stainless steel aluminum cold rolled and galvanized steel and even copper and brass in thicknesses ranging from 0 02 in.

Use the following simple guidelines to formulate and design the type of sheet metal bracket you will need to successfully meet your requirements.

Avoid large sheet metal parts with small bent flanges.

Bends are the most typical feature of sheet metal parts and can be formed by a variety of methods and machines which negate the absolute need for some of the below tips.

Bends should be toleranced plus or minus one half degree at a location adjacent to the bends.

The problem definition included producing guidelines regarding the two manufacturing methods of sheet metal.

Loading the starting point is determining what loading your metal part will be required to hold.

Avoid large sheet metal parts with small bent flanges.

Design for manufacturability sheet metal guidelines bends for the ease of manufacturing multiple bends on the same plane should occur in the same direction.

D 2 5t r see below the height can be less but it required secondary operations and is far more costly.

Sheet metal parts with a minimum of 0 9mm to 20mm in thickness can be manufactured.

When designing parts for laser cutting one should not make holes smaller than the thickness of the material.

Therefore exceptions can be there for complex features design.